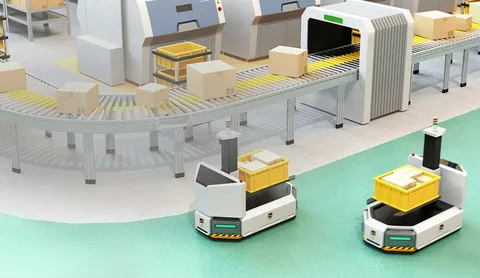

The automated guided vehicles (AGV) market is experiencing unprecedented growth, driven by the rapid adoption of automation technologies across various industries. AGVs are crucial in enhancing operational efficiency, safety, and productivity in manufacturing, warehousing, and logistics. These driverless vehicles, equipped with sophisticated sensors and software, navigate autonomously, streamlining material handling, transportation, and storage processes. As industries increasingly prioritize automation to remain competitive, the AGV market is evolving to meet the demand for smarter, more flexible, and cost-efficient solutions.

This PR content delves into the key trends driving the AGV market, explores the diverse applications of AGVs, and highlights the potential impact of this technology on the future of industrial automation.

Detailed Market Study: Full Report and Analysis

Market Trends Driving AGV Adoption

- Industry 4.0 and Smart Manufacturing The rise of Industry 4.0 and smart manufacturing is a major catalyst for the AGV market’s expansion. In this era of digital transformation, companies are leveraging advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), and big data analytics to create interconnected and intelligent production environments. AGVs, as an integral part of smart manufacturing, facilitate the seamless flow of materials and goods within factories, enabling real-time data collection and process optimization.

As manufacturers adopt these technologies to increase efficiency, reduce errors, and minimize labor costs, AGVs are becoming indispensable in automating repetitive tasks such as transporting raw materials, components, and finished products. The growing demand for smart, connected systems is pushing AGVs to the forefront of industrial automation.

- E-commerce and Warehousing Boom The e-commerce sector’s explosive growth has significantly impacted warehousing and logistics operations. Online retailers are facing increased pressure to deliver products quickly and efficiently, leading to a surge in demand for automated systems that can handle the high volume of orders. AGVs, with their ability to operate 24/7 without human intervention, are key enablers of this transformation.

In modern fulfillment centers, AGVs are employed to transport goods between different stations, automate storage and retrieval systems, and even assist in packaging. Their ability to navigate large, complex warehouse environments autonomously has proven essential in managing the logistical challenges of e-commerce.

- Labor Shortages and Rising Operational Costs Labor shortages, especially in industries like manufacturing and logistics, are accelerating the adoption of AGVs. These vehicles not only mitigate the impact of workforce constraints but also help companies reduce operational costs. By automating tasks traditionally performed by human workers, AGVs can lower labor expenses while maintaining high levels of productivity and accuracy.

Additionally, the cost-effectiveness of AGVs compared to traditional material handling systems is making them an attractive investment for companies looking to streamline their operations. As labor costs continue to rise globally, AGVs offer a sustainable solution to minimize expenses while enhancing operational efficiency.

- Safety and Workplace Efficiency Safety is a top priority in industrial settings, and AGVs play a critical role in reducing workplace accidents. Equipped with advanced sensors and AI-based navigation systems, AGVs can detect obstacles, adjust their speed, and avoid collisions, ensuring a safer working environment. By taking over dangerous or strenuous tasks, AGVs reduce the risk of injury to human workers, leading to improved workplace safety standards.

The ability of AGVs to perform tasks consistently and accurately also contributes to overall efficiency. Unlike human workers, AGVs can operate without fatigue, eliminating errors due to misjudgment or exhaustion. This consistency ensures that operations run smoothly, with fewer disruptions and downtime.

Key Applications of Automated Guided Vehicles

AGVs are revolutionizing a variety of industries, offering flexible and scalable solutions for material handling, transportation, and storage. Some of the most significant applications of AGVs include:

- Manufacturing and Production AGVs have become an integral part of modern manufacturing processes, especially in industries with high production volumes, such as automotive, electronics, and consumer goods. In production environments, AGVs are used to transport raw materials, components, and finished products between workstations, assembly lines, and storage areas.

Their ability to follow predefined routes or respond dynamically to changing production needs makes them highly adaptable. AGVs are also increasingly being integrated with robotic arms and other automated machinery, creating fully autonomous production lines that can function with minimal human intervention.

In the automotive industry, for instance, AGVs are used to transport vehicle parts between different production stages, enabling just-in-time (JIT) manufacturing practices. This reduces inventory costs and ensures that materials are available precisely when needed, improving overall production efficiency.

- Warehouse Automation and Logistics AGVs play a vital role in warehouse automation, where they are used for tasks such as goods transportation, inventory management, and order fulfillment. In large distribution centers, AGVs can transport goods between different storage locations, load and unload materials, and even assist in picking and packing operations.

The integration of AGVs with warehouse management systems (WMS) enables seamless coordination between the vehicles and other automated systems, ensuring that goods are stored, retrieved, and delivered efficiently. AGVs can be programmed to optimize routes, reducing travel time and energy consumption while improving order accuracy.

In the logistics sector, AGVs are increasingly being used in ports and airports to transport cargo between different terminals. Their ability to handle heavy loads and operate in harsh conditions makes them an ideal solution for automating large-scale logistics operations.

- Healthcare and Pharmaceuticals AGVs are finding innovative applications in the healthcare and pharmaceutical industries, where they are used to transport medical supplies, medications, and equipment within hospitals and laboratories. In hospitals, AGVs can autonomously navigate hallways, delivering critical supplies to patient rooms, operating theaters, and pharmacies, reducing the burden on healthcare staff.

In pharmaceutical manufacturing, AGVs are used to transport raw materials and finished products in highly regulated environments. Their precision and ability to operate in sterile conditions make them an ideal solution for handling sensitive products, ensuring compliance with strict industry standards.

- Retail and Supermarkets AGVs are increasingly being adopted in the retail sector to enhance customer service and streamline operations. In large retail stores and supermarkets, AGVs can assist with tasks such as restocking shelves, transporting goods from the stockroom to the sales floor, and even delivering items to customers in-store.

Retailers are also experimenting with using AGVs in automated checkout systems, where customers can place their items in an AGV, which then calculates the total cost and processes the payment. This technology not only improves the customer experience but also reduces the workload for retail staff, allowing them to focus on more value-added tasks.

- Agriculture and Farming AGVs are making significant inroads into the agricultural sector, where they are used to automate tasks such as planting, harvesting, and transporting crops. Autonomous tractors and harvesters equipped with AGV technology can operate continuously, reducing the need for manual labor and increasing overall productivity.

In large-scale farming operations, AGVs are used to transport harvested crops to processing facilities, ensuring that agricultural products are handled efficiently and with minimal waste. The use of AGVs in precision agriculture, where they collect data on soil conditions and crop health, is also becoming more common, helping farmers make informed decisions and optimize their yields.

Future Prospects and Challenges

The AGV market is poised for significant growth in the coming years, driven by the increasing demand for automation across industries. As AGV technology continues to evolve, we can expect to see even greater levels of intelligence, flexibility, and integration with other automated systems. The development of autonomous mobile robots (AMRs) that can navigate dynamically without fixed paths is also expected to complement AGV technology, offering even more versatile solutions for material handling.

However, the AGV market still faces challenges, such as the high initial costs of implementation and the need for advanced infrastructure, including navigation systems and communication networks. Additionally, ensuring the interoperability of AGVs with existing equipment and systems is crucial for maximizing their effectiveness.

Nevertheless, the long-term benefits of AGVs—such as reduced labor costs, improved safety, and enhanced operational efficiency—far outweigh these challenges. As industries continue to embrace automation, the AGV market is expected to grow at a robust pace, transforming the way businesses operate and shaping the future of industrial automation.

Key Companies Profiled

- JBT Corporation

- Kuka AG,

- Daifuku Co., Ltd.

- Kion Group AG

- Omron Adept Technologies, INC.

- AGVE Group, Inc.

- Murata Machinery

- Transbotics Corporation

- Oceaneering International Inc.

- Seegrid Corporation

Automated Guided Vehicle Market by Category

By Technology Type:

- Laser Guidance

- Magnetic Guidance

- Infrared Guidance

- Wire Guidance

- Inertial Guided

- Optical Guided

By Application Type:

- Transportation

- Distribution

- Storage

By Vehicle Type:

- Unit Load Carrier

- Pallet Truck

- Assembly Line Vehicle

- Tow Vehicle

- Forklift Truck

- Light Load Transporters

By End Use:

- Logistics

- Healthcare

- Automotive

- Manufacturing

- Food & Beverages

- Aerospace

By Region:

- North America

- Latin America

- Europe

- South Asia

- East Asia

- Oceania

- The Middle East and Africa

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer, Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware – 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube